The first question you might be asking is whether or not you should install a real skin head or a plastic head. Skin heads are certainly more authentic, but they are not necessarily a good thing for every banjo. The tension changes constantly with the temperature and the humidity, so be prepared for an ever-changing sound coming from your banjo. If you play old time style, like frailing or clawhammer, and you have an older banjo with an odd size rim, then you might HAVE to use a real skin head. If you are able to find a plastic head the right size, then you will save yourself a lot of headaches by using that instead. The larger the head, the more the tension will change and the harder the time you'll have trying to keep it in tune. I have a small banjo uke that has a real skin head, and I don't have any trouble at all keeping it in tune. The head is 5-1/4" in diameter, so it just doesn't stretch much

Okay, here we go. You have opted for a real skin head. The first thing you need to do is determine how large the piece of skin has to be. It needs to be larger than the rim by at least four inches in diameter so that you'll have enough skin to pull over the rim and back up through the tension hoop. A good place to purchase skins is Mid-East Manufacturing. They have good information about the different types of skin, thicknesses, and sounds that you can expect to get with the different types of skins.

The first step is soaking the skin in water. I soak the skin for 5-10 minutes, depending upon how thick it is. You don't want to waterlog it, but it needs to be supple. Next, you'll drape the skin over the rim of the banjo. Make sure you let the excess skin hang over evenly. Then take the round ring and put it on top of the skin and over the rim. Pull the skin gently to remove any wrinkles.

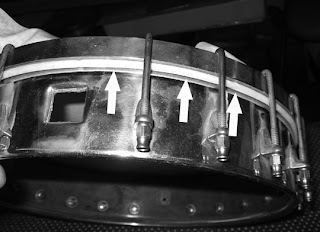

Next, you are going to put the tension hoop on. This is a little bit tricky, but not too hard. Take the edges of the skin and fold them up on top of the banjo head. The ring should remain about 1/4" on the rim. If you are not sure of the difference between the ring and the tension hoop, take a look at the very next post and you can see two circular pieces of metal. The round ring looks like a thick piece of wire that has been made into a circle. The tension hoop has flattened sides shaped into a circle.

Then take the tension hoop and put it on top of the skin-covered ring. The excess skin will be sticking straight up on the inside of the tension hoop. (This picture shows the brackets already on, but they actually won't be on yet.)

Make sure that you pull the skin between the ring and the tension hoop to remove any wrinkles or creases. The skin should also remain smooth on top.

Next, you will put all the brackets on and tighten them a little bit. You don't want to get the brackets too tight because as the skin dries, it will shrink. If you have the head too tight, then it will break when it dries. Once again, make sure that there are no wrinkles or creases in the top of the head or on the side where the ring and tension hoop meet.

When the skin is almost dry, you can cut off the excess skin. I use a razor knife and cut upwards and towards the tension hoop. This keeps me from accidentally cutting the top of the skin banjo head. It also keeps me from cutting myself! (I've been told I can cut myself on a bowling ball, but we won't go there...)

When the skin is dry, you can tighten the brackets to achieve the desired sound or tension. It should look like this.

2 comments:

Very nicely done :)

really helpful. thanks very much for posting

Post a Comment